A pump is an electro-mechanical device used to transfer liquids from one place to another place using high hydraulic pressure. Read on to know about transferring liquids, and its types and how we are handling. Liquids can be water, oil, chemicals, acids, etc. Tormac products are designed to handle only water. The water may be drinking water, aggressive water, seawater, or wastewater. Depending upon water PH value, Hardness, Viscosity, Temperature, Sand content, Chlorine ion density the pumps vary with different construction and technical equipment.

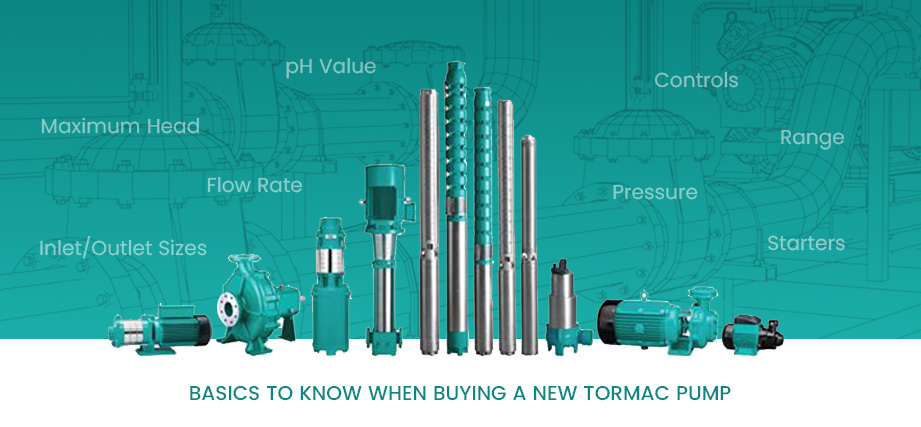

Next, we need to understand the water source from where the pumping should happen, under the ground or Surface source. Tormac has a wide range of pumps that can transfer water horizontally, vertically, inclined and declined to a great distance, with different material of construction and sizes to match all your needs. But, it is important to identify the type that will work best for your needs.

To drive a pump, you need a motor that runs on electrical or mechanical energy. Tormac is manufacturing electrical motors of Water filled / Oil filled with a wide ranges.

Flow rate:

The flow rate (Q) of a pump is useful volume flow delivered through its outlet section. Volume, flows, upstream of the pump outlet section, and purpose is taken into account when calculating the pump flow rate. Each pump has a specified flow rate measured in Liters per second (lps) / Liters per minute (lpm) / Cubic meter per hour (m3/hr) / gallons per minute (GPM), as we have mentioned on the product page. If you have a high flow, you will need a large diameter pump. You also need to think about what you plan to do with the liquid, be it decanting or transferring. Tormac pumps have maximum flow rates up to 5000m3/hr. Depending upon its applications, the right flow rate and head are necessary parameters to start selecting a pump.

Maximum head (H) and pressure (bar):

The maximum head of a water pump refers to the longest distance in terms of vertical height or Horizontal height it will be able to pump water. If you are looking for the best water pump, you will see details such as nominal Head and maximum flow rates.

The piping has an impact on the “maximum head” pressure, and this is where the “rated head” is best to observe. The “nominal height” represents the ideal height for which you should consider using it – most pumps can’t deliver above their nominal height. If you are measuring the height between your pump’s location and your highest point of water access, you should have a good idea of the pump you will need. Tormac has pumps that can pump the water up to a maximum height of 820 meters.

Flow (Q) Vs Head (H):

Pump sizing involves matching the flow and pressure of a pump required for the process. The flow (Q) and head (H) both are reciprocal to each other. When the water is pumped to a great height, most of the energy will be consumed to lift the water, so the flow will reduce and vice versa. So, this is mandatory to understand this concept before you select any pump.

Inlet & Outlet Sizes:

Most pumps except borehole pumps have an inlet size between 1 and 6 inches but in some cases, it can be more. Centrifugal water pumps also operate in a similar way i.e. sucking in water from the inlet and discharging it through the outlet valve. In this case, the bigger size of an inlet valve, the more water can be pumped out and the faster it will do the job.

With Borehole pumps, as it submerges under the water there is no specific inlet valve as like in Centrifugal pumps. The interconnection between the motor and pump is the water inlet entry. Here we talk only about the outlet sizes in Inches or mm. One should know about the Outlet sizes for proper pipe selection and Valves selections. Tormac pumps got a sizes up to 6” under standard ranges. For customized can go even higher sizes. For personalized use, we can have even more sizes.

Starters and controls:

Tormac has specialized in bespoke control panels that meet the specific needs of domestic, industrial and specialty applications. It is mandatory to have the control panels specified by the brand for a perfect start, operation, stop and protection of the pump and the motor. If you install a good control panel, it can protect the products from failure. Tormac control panels are installed to ensure trouble-free operation, long product life, energy savings and high performance.

Final thoughts:

Tormac thinks outside the box to offer the best possible solution without limiting ourselves to a particular supplier’s range. All pumps provide a full end-to-end service for all areas and customized pumping systems. It has resulted in a tremendous reputation and wide acceptance across all sectors of the industry. As a customer-centric organization, we foster innovation, learning, and collusion. The employees are our greatest strength; their knowledge and expertise allow Tormac to provide cutting-edge industrial solutions. If you want to learn more about Tormac please visit: Tormac Pumps