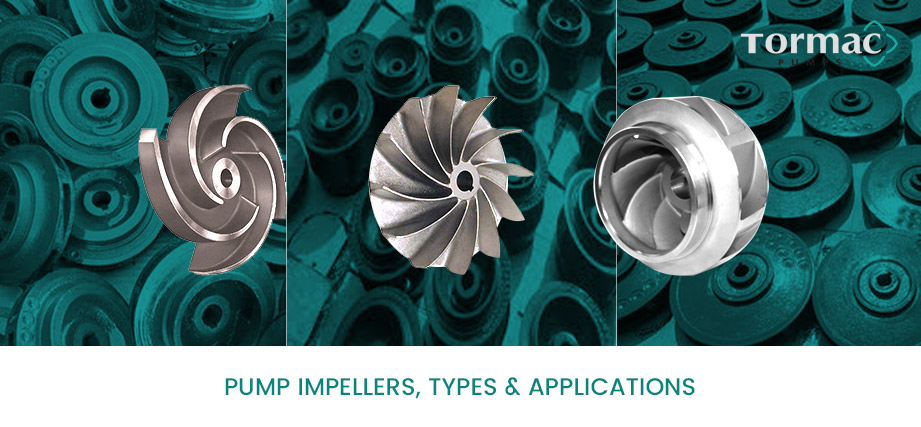

Pump Impellers, Types and Impacts

The specification of the right centrifugal pump for an application involves various considerations. One of them is the right choice of impeller type. Each type of impeller offers different performance characteristics that make it suitable than the others for a particular application.

Main points to impeller selection:

1- Efficiency and NPSHr/a

2- Head & Flow

3- Material compatibility

4- Solid content handling

Main types of impeller:

1- Open impeller:

- Has vanes that are open on both sides

- To handle solid content

- Require a higher NPSH

2- Semi-Open Impeller:

- Has a back-wall shroud

- Pumps with a small amount of soft solids

3- Closed impeller:

- Has enclosed at the back and front

- Low NPSHr and more efficient flow

- For large pumps transferring clean liquid

4- Vortex Impeller:

- Similar to a semi open with more space in the volute

- Ideal for dirty fluids

- Minimal risk of clogging

- Low efficiency

5- Cutter Impeller:

- With sharp edge to handle solids

- Grind any solids

- Ideal for sewage water

- Low efficiency